FEATURES

The Control Tower for Modern Manufacturing

Three integrated modules that give you complete visibility from PO to delivery, across your floor and your supply chain.

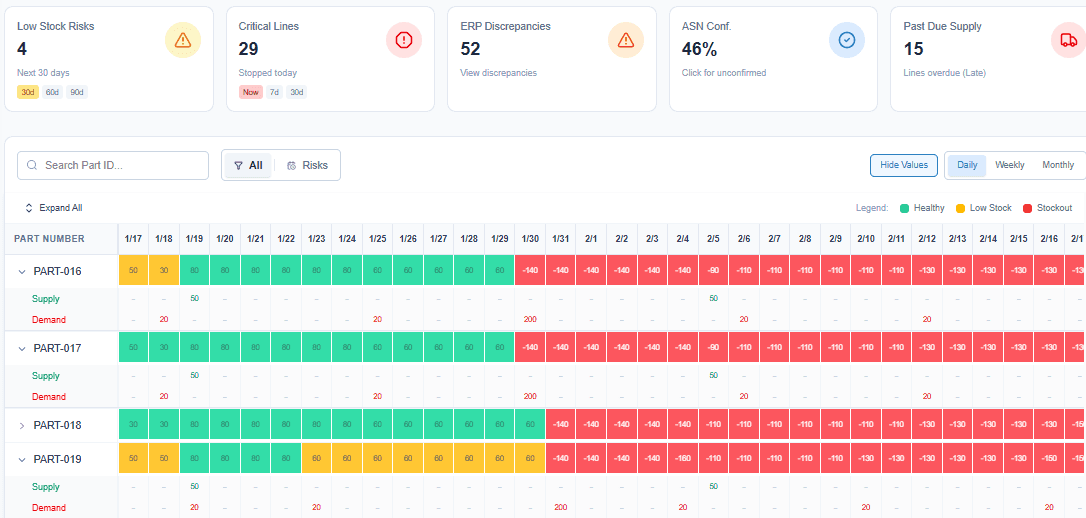

SHORTAGE MANAGER

Prevent Line Stoppages Before They Happen

Our core engine calculates the daily running balance for every part number, identifying the exact "Cliff Date" when you will go negative. No more monthly buckets or ERP guesses.

- Daily-level granularity (not monthly buckets)

- Dynamic Stockout dates

- Visual "Christmas Tree" Heatmaps

- Priority ranking and Buyer assignment

- Export to Excel with Executive Summary

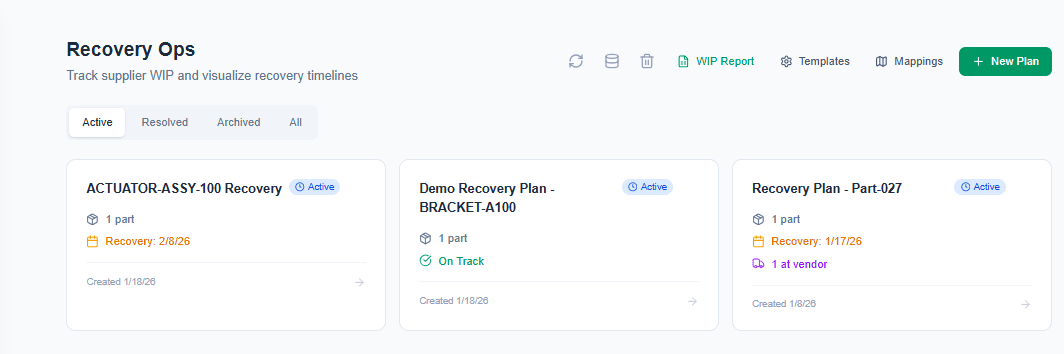

RECOVERY OPS

Track External WIP Across Your Supply Chain

For job shops and manufacturers with external processing, Recovery Ops tracks where every part is - whether it's at Plating, Heat Treat, Painting, or your floor.

- Sub-tier vendor milestone tracking

- WIP progress uploads from vendors

- Kanban-style board for recovery status

- Automated vendor reminders

- WIP Reports for production meetings

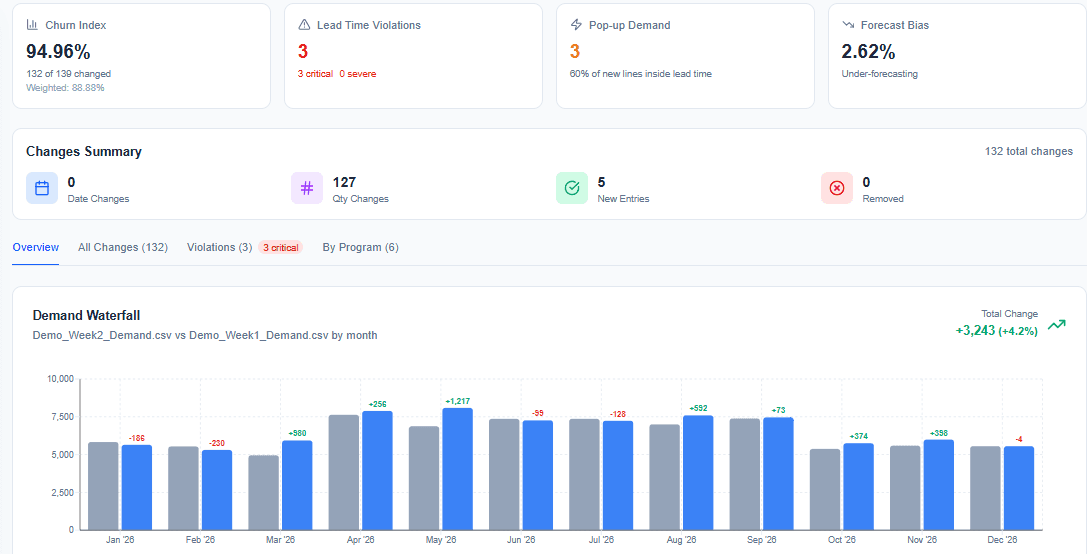

SIGNAL AUDIT

Validate Demand Before You Commit Capacity

Stop buying for 'Ghost Demand.' Signal Audit compares customer forecasts week-over-week to quantify churn, catch lead time violations, and validate demand stability before you cut a PO.

- Stability scoring and churn metrics

- Frozen zone violation detection

- Week-over-week demand comparison

- Pop-up demand detection (new lines)

- Evidence package Excel exports